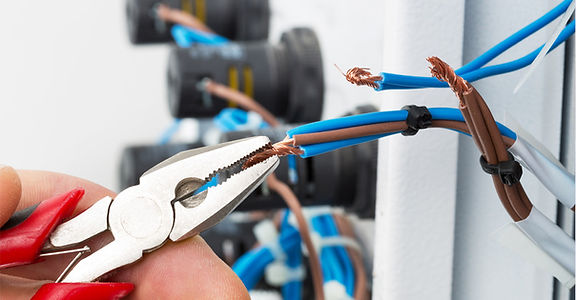

Custom cable assembly can be an intricate and complex process that requires comprehensive systems and procedures to ensure consistent quality. Braemac has attained AS/NZS: ISO 9001 2015 and Medical ISO13485 accreditation. Our experienced production team are trained and accredited to IPC/WHMA-A-620 worldwide standards.

Loom Management

Untangle the mess. Simplify every connection.

Box Builds

Configuration, assembly and verification of your products.

Refurbishment and Service

Extending product life spans through preventative maintenance.

Located centrally in Sydney, our facility is well equipped to accommodate electronic assembly production and QA testing.

Manufacturing Facility

Extensive network of local and international component suppliers enabling competitive electronics manufacturing without the hassle of self-sourcing components.

Sourcing Capabilites

Project Management

Braemac offers a turn-key electronics manufacturing service to suit your project requirements.

Design Support

Braemac can assist with your cable assembly design and documentation.

CABLE &

PRODUCTION

Australian Industry has a need for local manufacturing services for cables, harnesses, sub/final assembly and testing of their products.

Braemac’s local manufacturing ensures a higher quality build standard, quick solutions to engineering problems and faster lead times to meet your ever-changing production schedules.

Cable assembly is an intricate and complex process that requires comprehensive systems and procedures to ensure consistent quality and adherence to strict regulatory requirements. Braemac’s experience in the industry coupled with its in-house Engineers, ensures that pinpoint accuracy is used in its manufacturing processes.

Our Engineers are driven by the need to ensure the precision of customers’ specifications and drawings, working closely with each customer to maximise product accuracy. Braemac’s long-standing experience of market trends ensures that individual customer requirements are met. Additionally this provides access to the latest design qualities that lead to the most productive and functional assembly possible.

Combining a global product sourcing network, with our extensive product range and local manufacturing facility, Braemac customers can benefit from rapid response times and ultimately, maximising return on investment.

Products and Services

Accreditations

Custom Looms and Harnesses

Tailored interconnect solutions covering a diverse range of industries and applications.

Prototype Builds

If your project requires assistance with first stage prototyping, Braemac can offer their team to assist.

Full Anti Static Procedures

Braemac’s production facility is fully compliant with the latest anti-static procedures to protect your sensitive components.

Full Bar Coding

From bar coding your completed products cartons to bar coding each individual component, Braemac has a vast array of bar coding options to suit your needs.

Programming Services

Programming of BIO & EPROM, Microcontroller Chipsets.

Assembly and testing Clean room available ISO13485 certified for medical cable harnesses and assembly of electronic components and sub-assemblies.

Medical Equiptment

Warehousing Facilities

With two warehouse options, Braemac can accommodate and manage your component inventory whether it’s large and bulky or intricate and delicate.